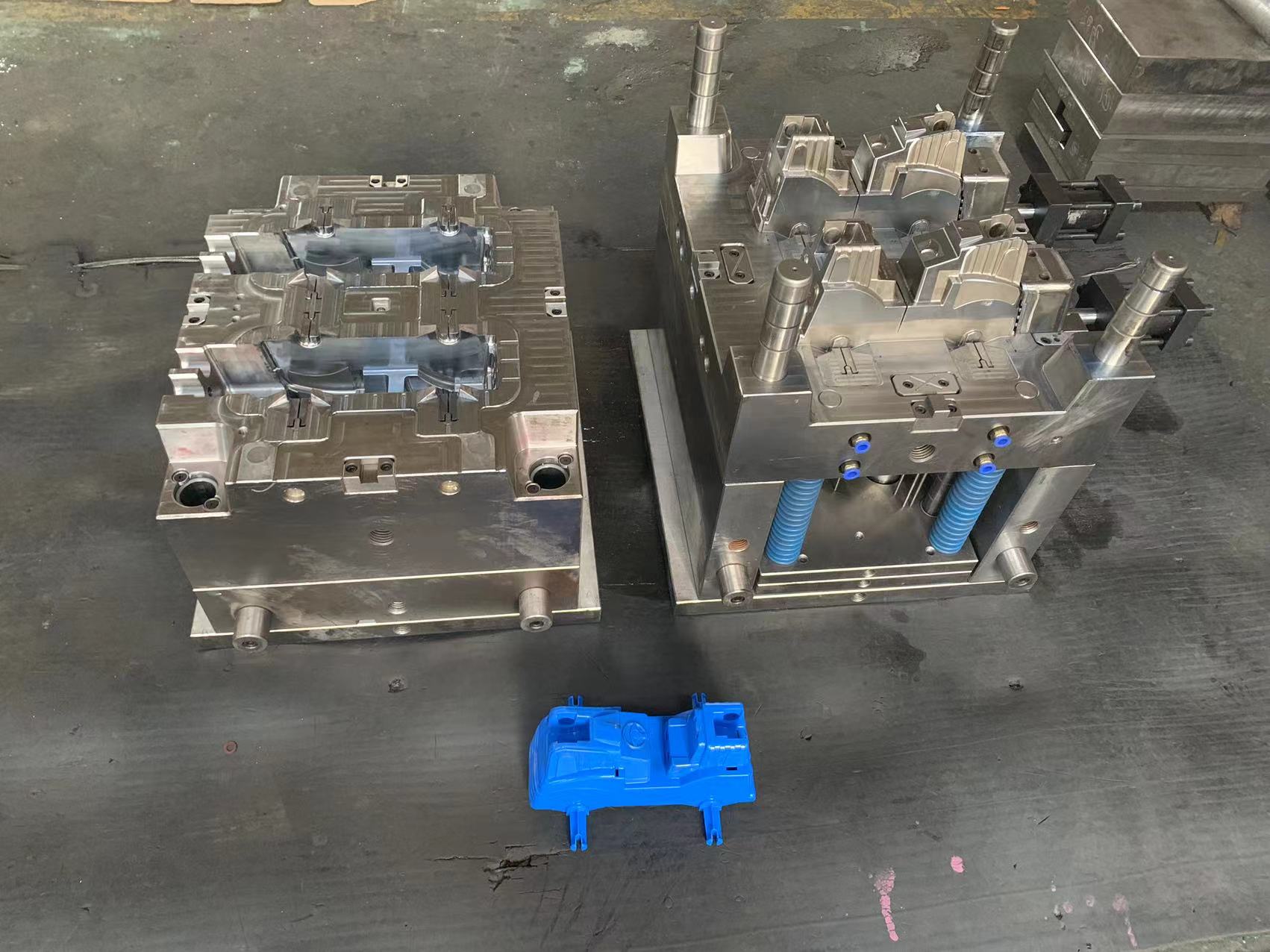

China Plastic moulds are as simple as this

When a piece of equipment or part of the machine fails, the replacement part must be ordered. If your machine is custom, it means you will need another part of the customization. However, this may take a while, depending on the complexity of the part and what material is made. However, if you already have a part of you made of injection molds, then ordering a part of you and waiting for it to arrive is a simple matter. Plastic molds use a quick way to get the parts you need in the shortest time and are not expensive in price, you can afford them.

The first synthetic plastic was created by scientist Alexander Parkes in 1855. It is not expected that plastic molds will revolutionize the world and change the way companies think and manufacture parts. Injection molds are quick and easy, and most importantly, they are inexpensive, you can get plastic parts made at low cost as soon as possible, because you need them, plastic is notoriously easy to use and surprisingly durable. This is why the use of plastics is so common in manufacturing. This is the best solution for a large production demand.

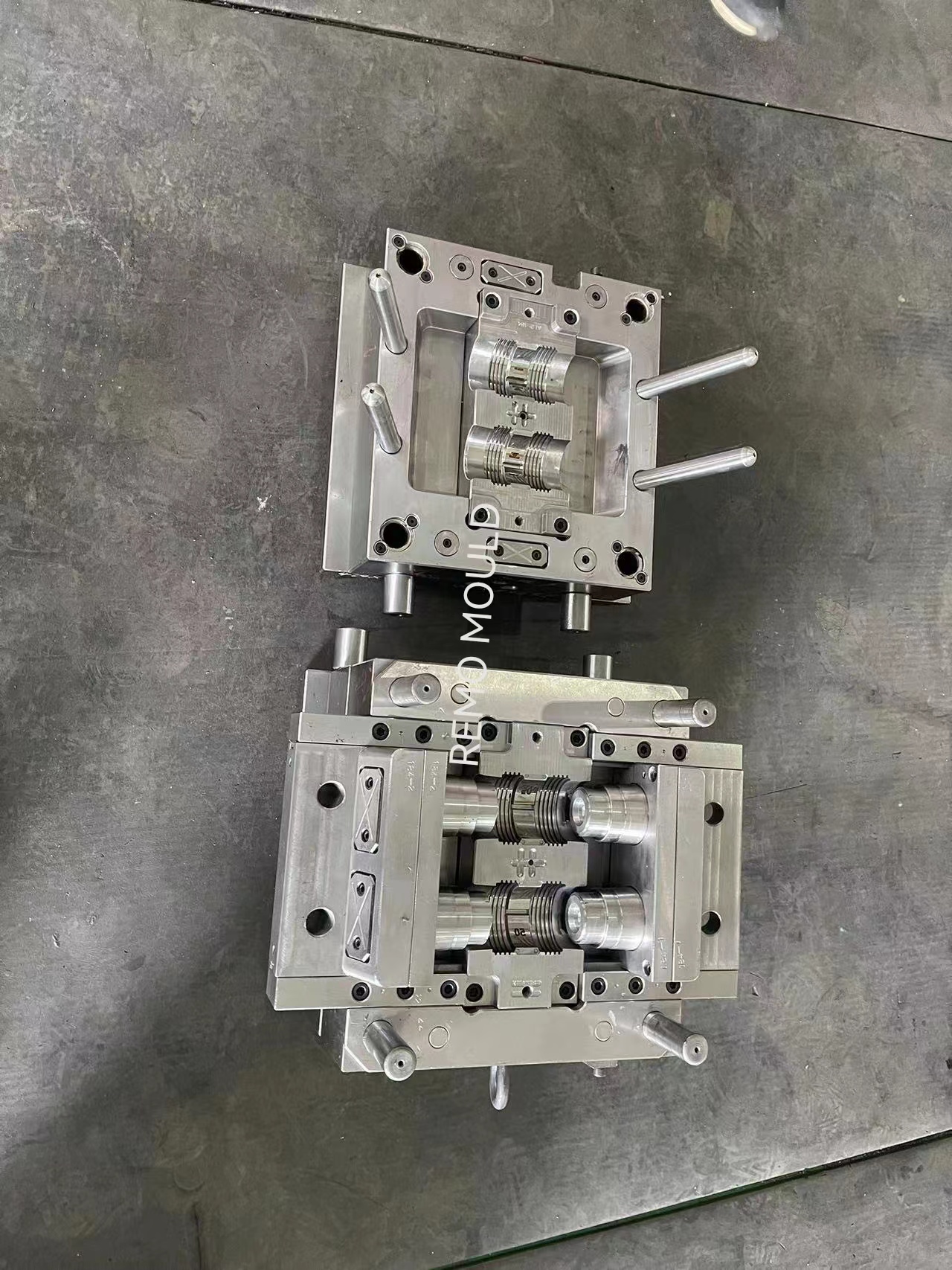

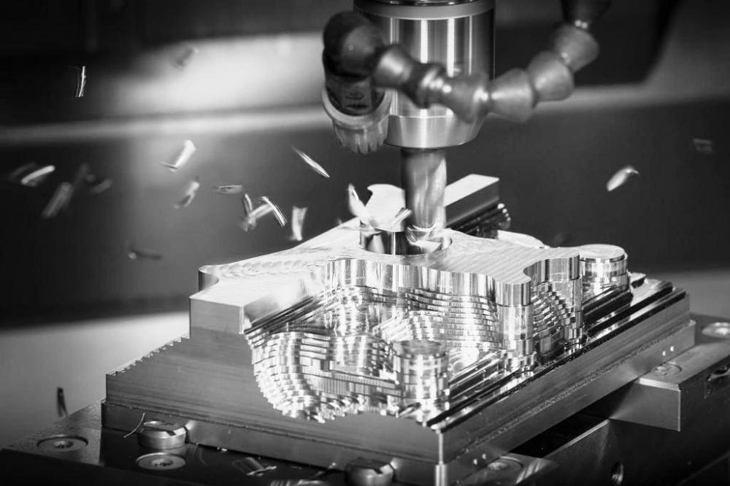

The process of molding plastic molds is quite simple. The plastic pellets are fed into the injection chamber of the hopper injection molding machine. The reciprocating screw inside the injection chamber ensures that the body of the particle inflowing machine is stable and uniform. The granules then pass through a heating element to melt the plastic. The plastic is melted and then fed through the nozzle into the mold cavity. From the cavity, plastic is injected into the injection mold itself, where the movable plate applies pressure to ensure that the plastic hardens, which is a simple but very effective method.

The widespread use of plastic injection molding is due to its ease of use to a large extent. In fact, plastics are inexpensive and can be manipulated to almost any shape and certainly not harmed. If you use plastic parts, just keep some extra parts on hand so that you don't have to worry about partial failure and take time to produce. By taking this approach, you can already give the shape you need in a short time, which is the advantage of plastic molds, which can save a lot of time and money.

welcome to email us for further contact frank@remomould.com