Custom Molds Manufacturing is art and science

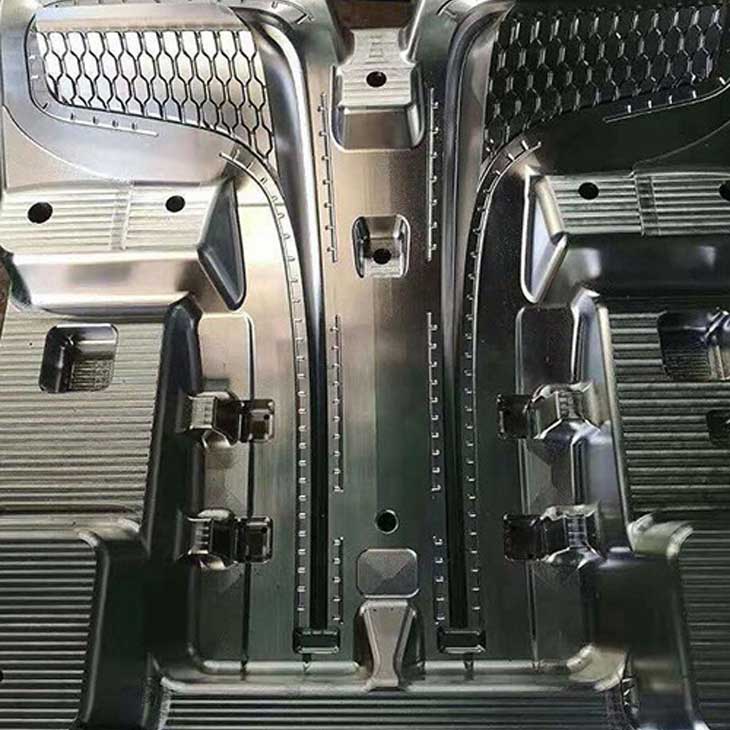

It takes seasoned tooling engineers to spot trouble areas and to modify designs to achieve the functionality needed for the part. Catching issues before a mold is made can save a lot of time and money.

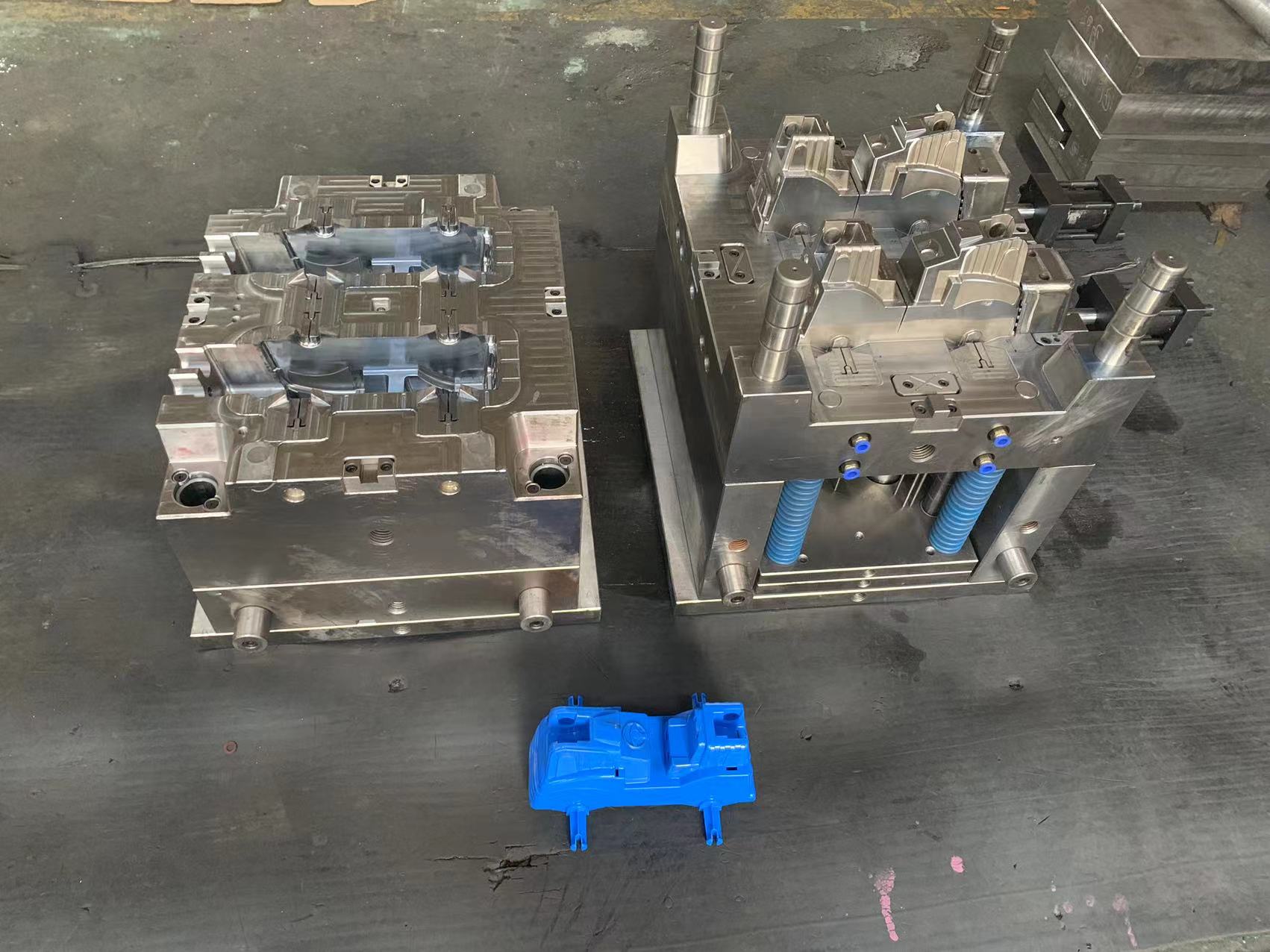

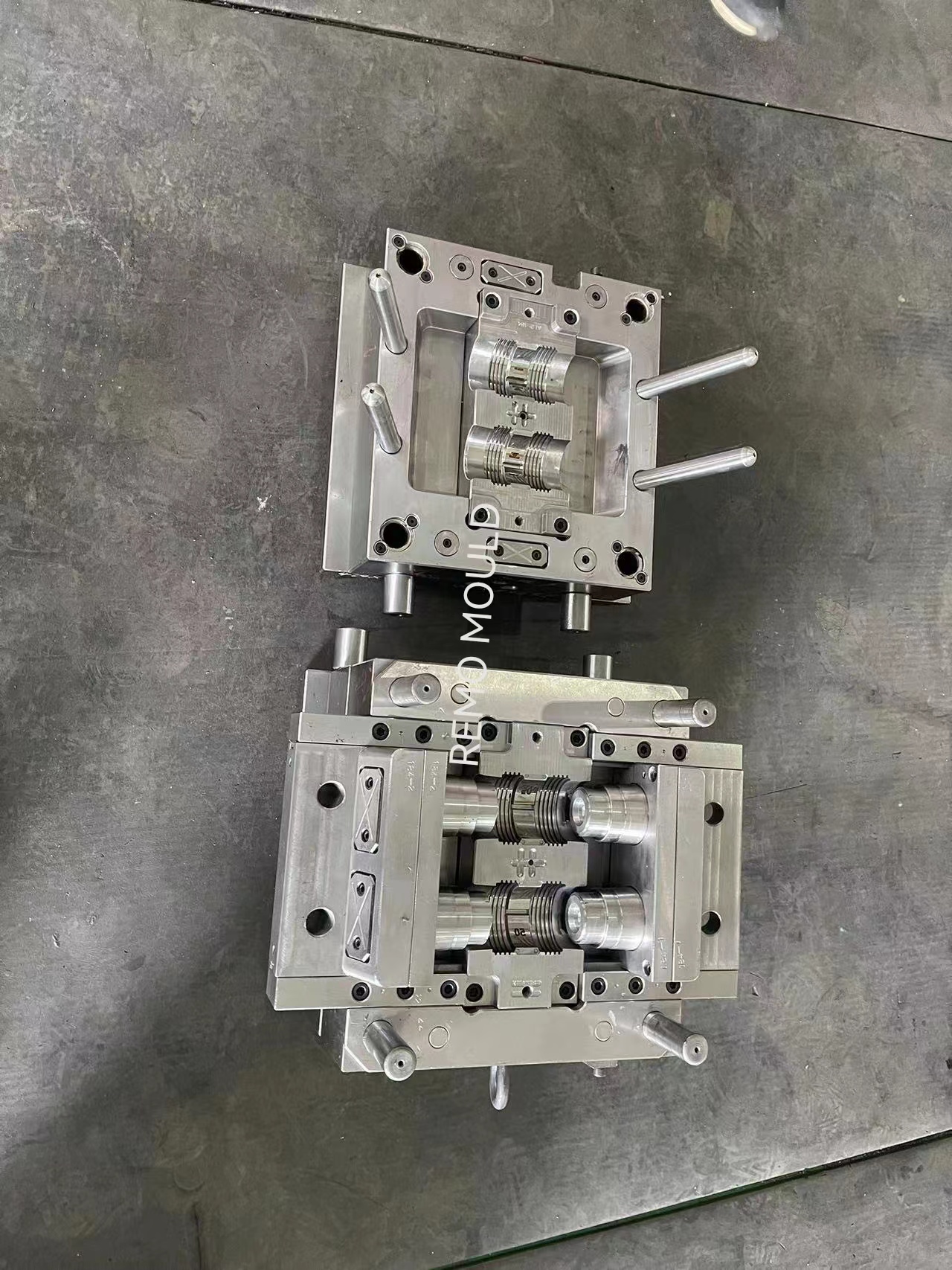

Making an injection mold can be done many different ways. Some are inclined to cut corners to reduce costs in the short-term, only to find that the total cost of ownership is greater over the life of the injection mold. At Ferriot, we have the customers’ interests in mind, and we have molds built to proven standards that incorporate durability, functionality and cost effectiveness over the life of the mold.

For us, it’s about accountability

Our productivity as a manufacturer and our ability to turn out superior products depends on ideal mold designs.

We invite you to push us. In one such case, an original equipment manufacturer (OEM) of gas pumps challenged us to convert a metal part at the boot of a gasoline nozzle into a thermoplastic component. Ferriot engineers helped develop an innovative plastic alternative that resists gas vapors, allowing the OEM to save money without sacrificing functionality.

Ferriot engineers, in this case, helped set in motion a new course for the production of gasoline pumps.

Call us with your innovative ideas for transforming — and economizing — the products and equipment of tomorrow. As one of the early engagement companies in plastic mold making and production, we have been on many pioneering journeys to assist OEMs in bringing new products to market.